Every serial number.

Every event. Forever.

Build complex assemblies with confidence. Hegemi creates a complete digital twin of every serialized unit you manufacture — tracking attachments, swaps, issues, and history down to the individual component.

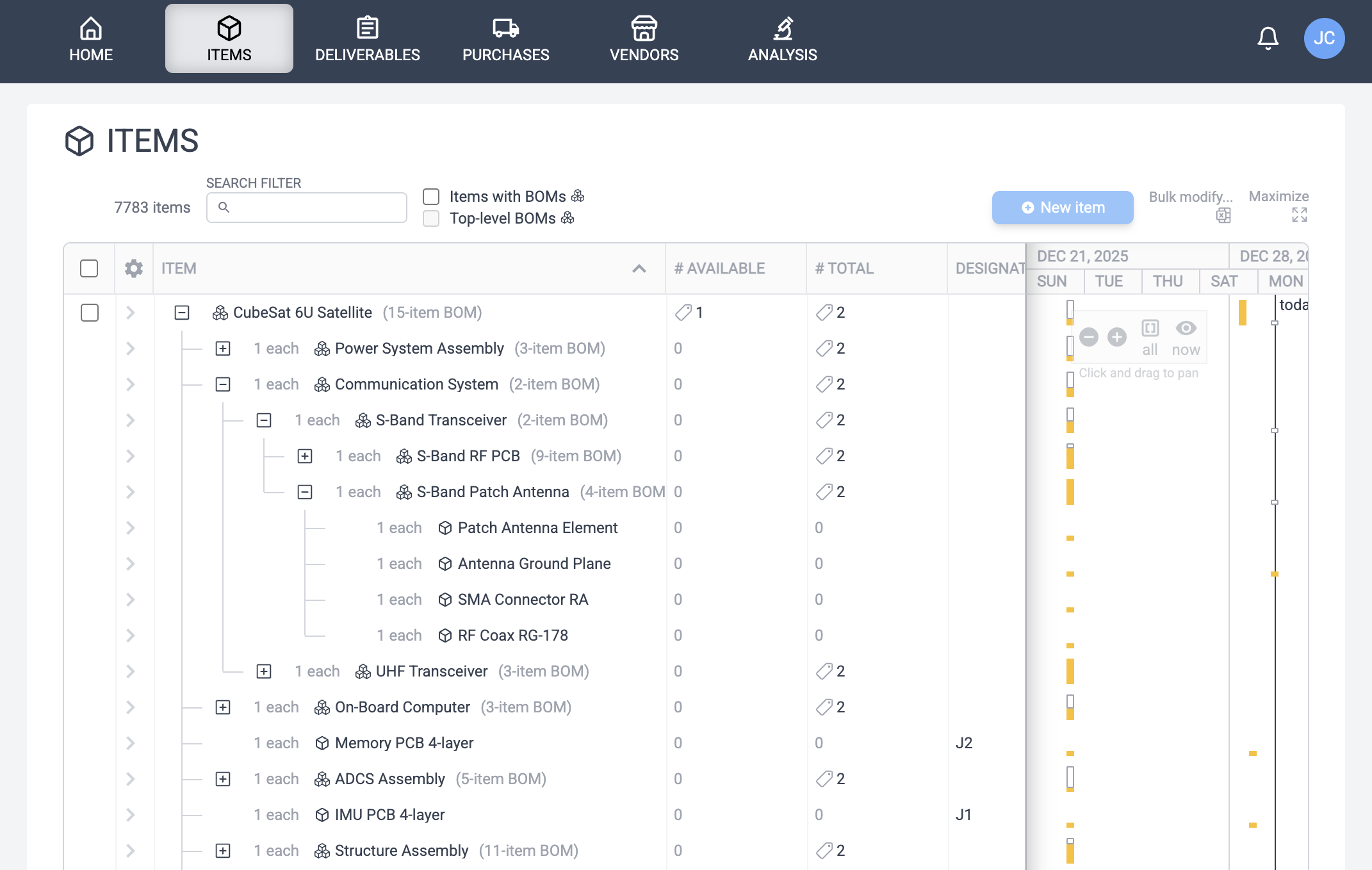

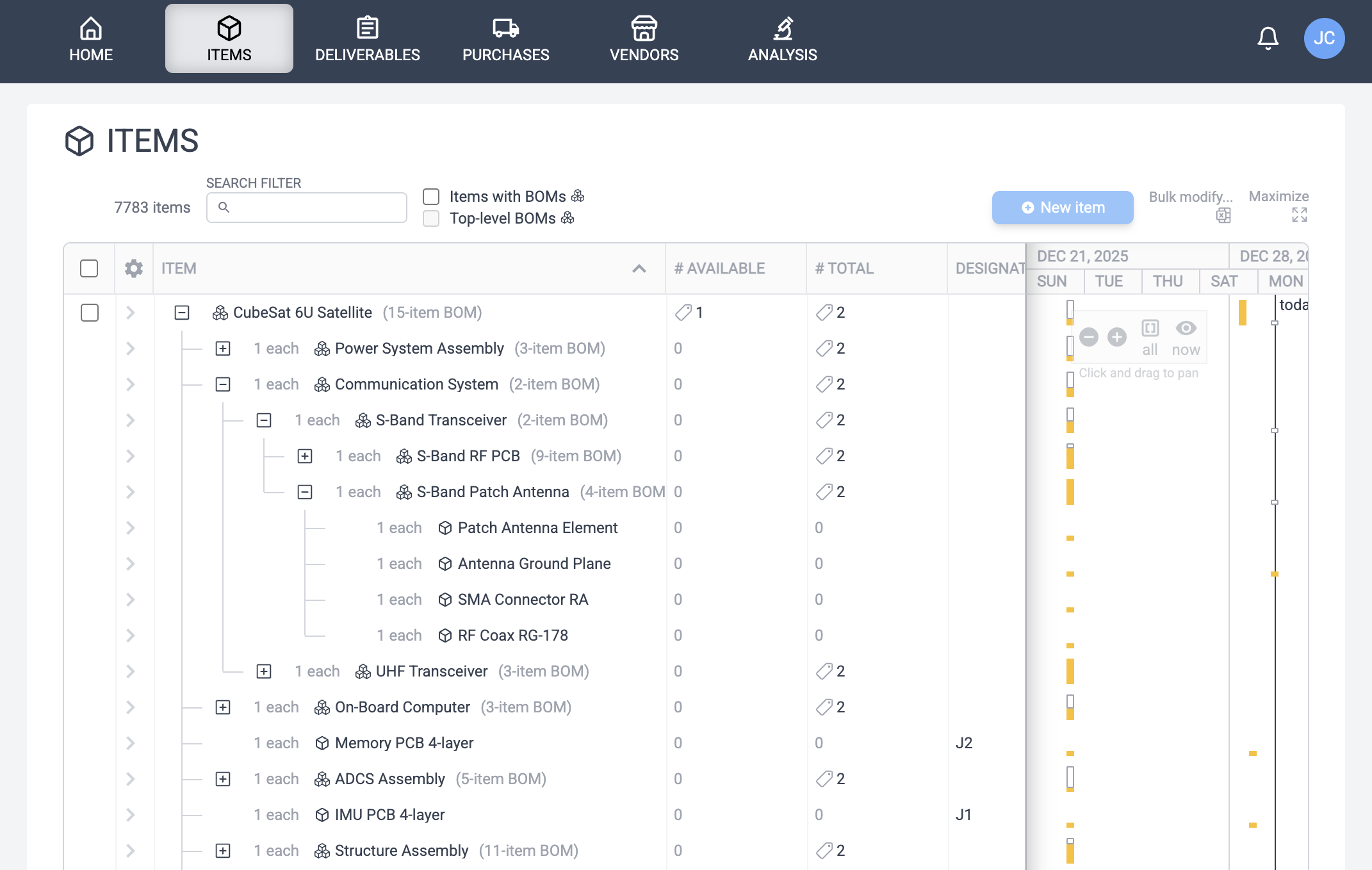

Built for complexity

When spreadsheets can't keep up with your hierarchical BOMs, component swaps, and serialized tracking needs.

Digital Twin

Every physical instance has a digital counterpart. Track serial numbers, BOM revisions, and build state — creating a complete virtual replica of your manufactured goods.

Inventory Analysis

Calculate shortages across complex hierarchical BOMs. Factor in partially-built instances and auto-generate purchase orders based on vendor lead times.

Activity Histograms

Visualize who is doing what and when with Gantt-style charts. Spot bottlenecks, track progress, and see at a glance where work is happening across your organization.

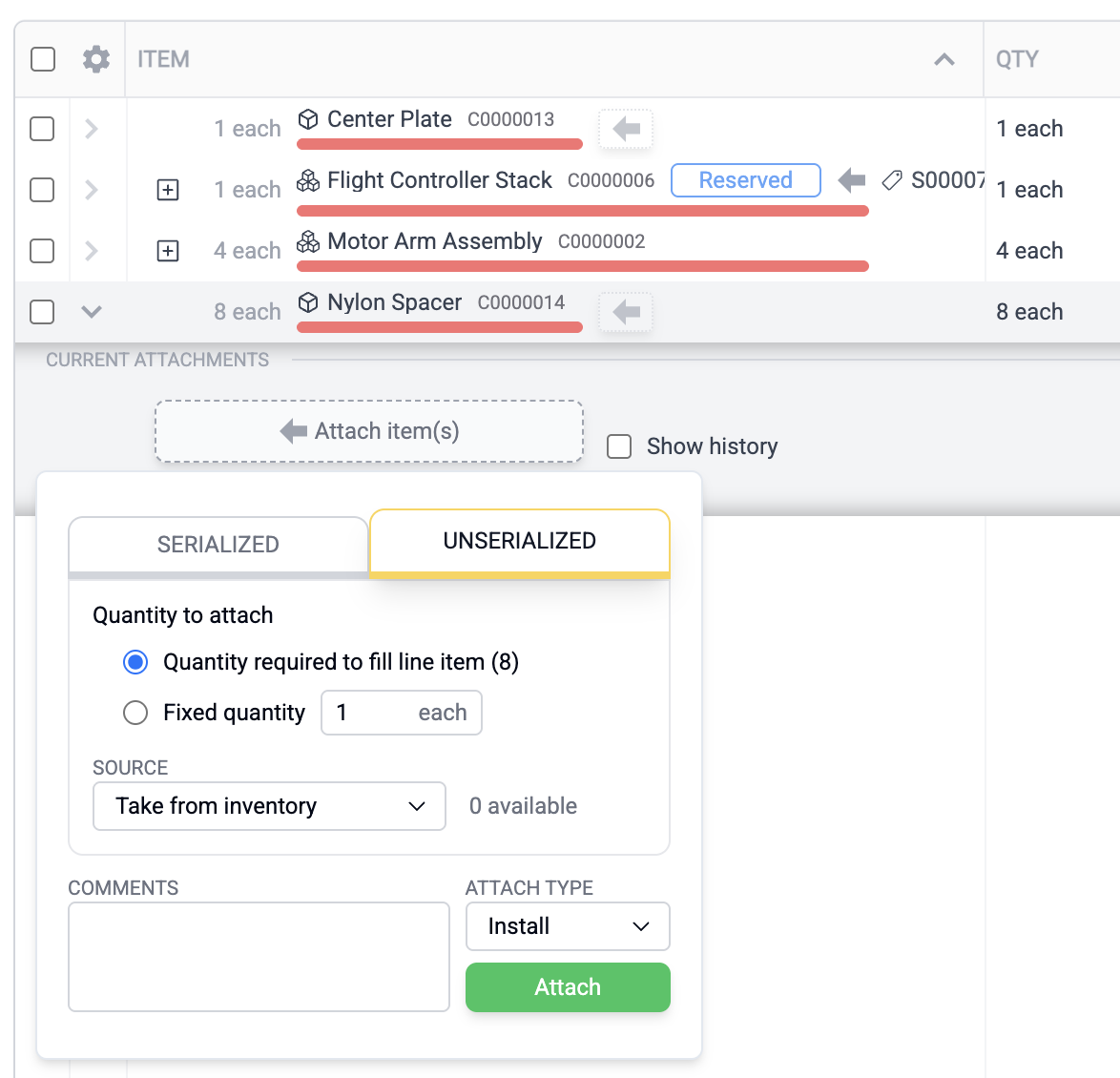

Full Traceability

Know exactly which part went into which unit. Track swaps, repairs, and complete attachment history — perfect for compliance, quality, and debugging field issues.

Know exactly what you need

Don't guess what to order. Hegemi's Inventory Analysis engine examines your hierarchical BOMs, checks current stock across all your partially-built instances, and tells you exactly what's missing.

- Factor in existing attachments on in-progress builds

- Auto-generate purchase orders grouped by vendor

- Swap in existing sub-assemblies from inventory

- Non-destructive — run scenarios without commitment

Track every move

When a component is swapped from one unit to another, Hegemi records it. When a technician flags an issue, it's logged forever. This isn't just inventory — it's a living history of your fleet.

- Full attachment history for every component

- Track who did what and when

- Perfect for compliance and quality audits

- Debug field issues with complete context

See activity at a glance

Every table in Hegemi displays Activity Histograms — compact Gantt-style visualizations showing when events occurred. Instantly see what's being worked on, what's idle, and patterns over time.

- Amber bars for direct events on each entity

- Hollow bars for descendant activity in sub-assemblies

- Expandable event detail for full context

- Adjustable timescale from hours to months

Built for the whole team

From engineers defining BOMs to technicians building units to managers tracking progress.

Managers

- •Build progress visibility

- •Fleet status tracking

- •Activity monitoring across the org

Engineers

- •Hierarchical BOM definition

- •Item documentation & notes

- •Purchase order submissions

Technicians

- •Virtual build instructions

- •Issue logging & tracking

- •Component attachment workflow

Accounting

- •Cost tracking per deliverable

- •Auto purchase order generation

- •Vendor order history

Simple, transparent pricing

Start free, upgrade when you need more. No hidden fees, no surprises.

Free

Perfect for small teams getting started

- Up to 3 users

- 150 items

- 6 months event history

- Full BOM hierarchy support

- Basic inventory analysis

Professional

For growing teams with complex needs

- Up to 15 users

- Unlimited items

- Full event history

- Advanced inventory analysis

- Purchase order workflows

- Priority support

Enterprise

For organizations at scale

- Unlimited users

- Unlimited items

- Full event history

- Custom integrations

- Dedicated support

- SLA guarantees

Ready to build with confidence?

Join teams who've replaced spreadsheets with a purpose-built system for tracking complex assemblies. Start free, no credit card required.